Used Rotary Screw Cappers

BPDM can supply a variety of Used Rotary Screw Cappers, either as-is, reconditioned or rebuilt. Machines are also commonly supplied ready for production.

Other Types of Cappers

Rotary Plastic Capping Turrets used in a Monoblock or Triblock

Learn More About Berks Plant Design and Maintenance, Inc.

HOW IT WORKS

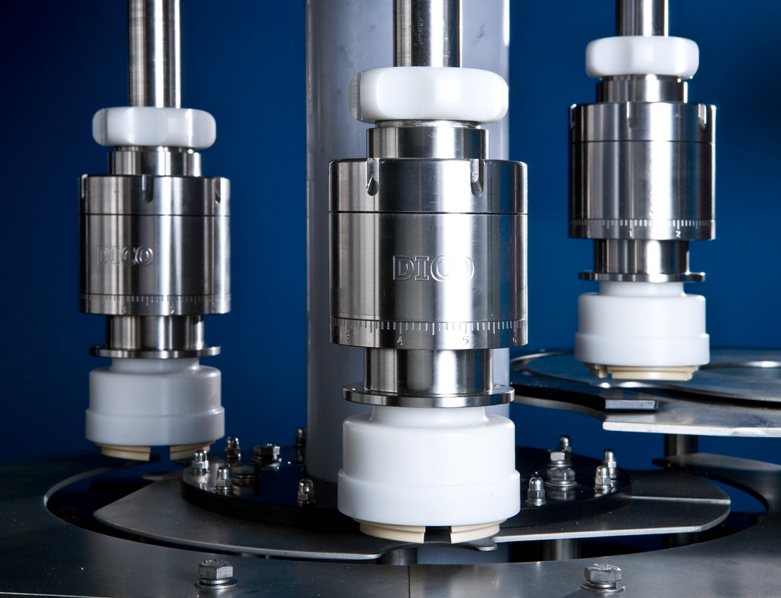

Used Rotary Screw Cappers achieve high production rates as containers travel through the system in continuous motion. Containers travel through Used Rotary Screw Cappers using container specific bottle handling change parts. These nearly always consist of an infeed screw, infeed star wheel, and discharge star wheel. The method of controlling bottle rotation while the cap is applied varies depending on the machine design. A rotating turret with multiple capping chucks are aligned with containers below using these bottle handling change parts. Each individual cap is applied and torqued by an individual chuck with torque control clutches driving each chuck. Caps are fed single file down a chute or escapement where caps are transferred one at a time into each capping chuck. The method of cap transfer varies depending on machine design. Caps are oriented to travel down the cap chute using a variety of sorting methods. Rotary Capping Turrets are often integrated with a filler or rinser/filler to produce a monoblock filler/capper or triblock rinser/filler/capper.

COMMERCIAL APPLICATION

Used Rotary Screw Cappers are designed to run much higher speeds than inline chuck or screw cappers. Used Rotary Screw Cappers' speed capacity is dependent on both the number of capping heads as well as sorting capacity and bottle/cap configuration. Used Rotary Screw Cappers also by design maintain very accurate torque settings as each chuck is driven by clutches. Depending on cap size and type, caps may be transferred to the chucks using a cap transfer button, a cap transfer star, and in some cases the caps are stripped from the chute by the neck finish of each container. Used Rotary Screw Cappers are used in the food, beverage, dairy, chemical and pharmaceutical industries.

EXAMPLE IMAGES - FOR ILLUSTRATION PURPOSES ONLY

-

Used Rotary Chuck Capper

-

Used Rotary Chuck Capper

-

Used Rotary Chuck Capper

Cap Feeders

Bulk Cap Elevator and Cap Blower

Why it is Used with Cappers

Bulk Cap Elevator

Bulk Cap Elevators are used to automatically maintain the amount of caps in a cap sorter allowing for optimal sorter operation while eliminating the need for operators to load caps and maintain reasonable quantities of caps.

Usually, the operation of the elevator is integrated to the capper using a variety of cap level sensors.

Cap Blower

Cap Blowers use filtered air to blow caps to a cap sorter utilizing tubing that guides the caps to the cap sorter.

Cap Blowers can be advantageous because they can feed caps at a high rate, and can be placed further away from the sorter itself.