Used Inline Steam Lug Cappers

BPDM can supply a variety of Used Inline Steam Lug Cappers, either as-is, reconditioned or rebuilt. Machines are also commonly supplied ready for production.

Other Types of Used Inline Cappers

Learn More About Berks Plant Design and Maintenance, Inc.

HOW IT WORKS

Used Inline Steam Lug Cappers are designed to work with standard lug caps, deep skirt lug caps, and push on lug caps where the finished product requires vacuum in the head space of the container. A substance known as plastisol lines the top of the cap to provide a hermetic seal. Caps are fed single file down a chute to a chute end or escapement where caps are stripped one at a time by the neck finish of the traveling bottle. A steam fed pre-heat chute section softens the plastisol liner just prior to application. Caps are oriented to travel down the chute normally using vertical pin sorters or elevator sorters depending on the cap and speed requirements. Bottles or containers are stabilized through the capping machine using a side belt system. Simultaneously, dual belts apply significant down pressure on the closure. These belts travel at different rates which is what actually applies torque to the lug cap. From introduction of the cap to the discharge of the capped product, a tunnel is consistently flooded with steam. Upon discharge this steam condenses which pulls a vacuum in the head space of the container.

COMMERCIAL APPLICATION

Used Inline Steam Lug Cappers are normally used in the food and beverage industries. Many of the closures used with steam lug cappers have a "button" that is pulled down in the center of the cap by the vacuum. When the cap is removed by the consumer or if the product was not produced properly, this button elevates as an indication that the product is unusable or has been opened previously. The machine design inherently lends itself to operation at high rates of production with maximum rate dependent on a machine specific design.

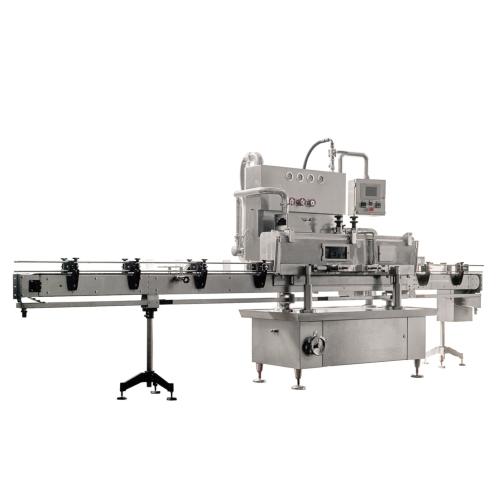

EXAMPLE IMAGES - FOR ILLUSTRATION PURPOSES ONLY

-

Used Inline Steam Lug Capping Machinery

-

Used Inline Steam Lug Capping Machinery

-

Used Inline Steam Lug Capping Machinery

Cap Feeders

Bulk Cap Elevator and Cap Blower

Why it is Used with Cappers

Bulk Cap Elevator

Bulk Cap Elevators are used to automatically maintain the amount of caps in a cap sorter allowing for optimal sorter operation while eliminating the need for operators to load caps and maintain reasonable quantities of caps.

Usually, the operation of the elevator is integrated to the capper using a variety of cap level sensors.

Cap Blower

Cap Blowers use filtered air to blow caps to a cap sorter utilizing tubing that guides the caps to the cap sorter.

Cap Blowers can be advantageous because they can feed caps at a high rate, and can be placed further away from the sorter itself.