Used High Level Case Depalletizers

BPDM can supply a variety of used high level case depalletizers, either as-is, reconditioned or rebuilt. Machines are also commonly supplied ready for production.

Other Types of Used Depalletizers

Learn More About Berks Plant Design and Maintenance, Inc.

HOW IT WORKS

Cases are discharged from Used High Level Case Depalletizers at a height slightly above that of a pallet load of full cases. These cases are normally then fed downstream after conveyance through an unscaser or decaser in order to remove containers or other products from a case. Used High Level Case Depalletizers position full cases of product layered on a pallet at the required discharge height of each case. Once this height is reached, each case layer is swept from the pallet, presenting the cases single file for use as necessary downstream. Each time a layer is completed the entire load is elevated to a position that allows the next layer to be swept off the pallet. Between each layer a slip sheet is in place, which is removed and placed in a receiving magazine. Each layer of cases are normally alternately formatted (every other layer), so that they interlock the multiple layers in order to generate a stable pallet, therefore requiring a different singulation method alternating by layer. After all layers are discharged from the pallet, each skid is placed into an empty pallet magazine. Used High Level Case Depalletizers are normally utilized in conjunction with high speed packaging lines.

COMMERCIAL APPLICATION

Used High Level Case Depalletizers are utilized in production lines with higher speed requirements and may save conveyor footprint space as cases can be elevated and conveyed overhead once fed from the case depalletizer. However, in almost all scenarios relatively complex platforms are utilized for operators to operate the equipment.

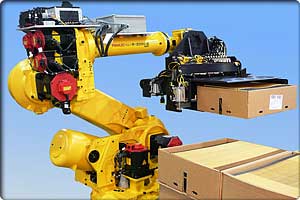

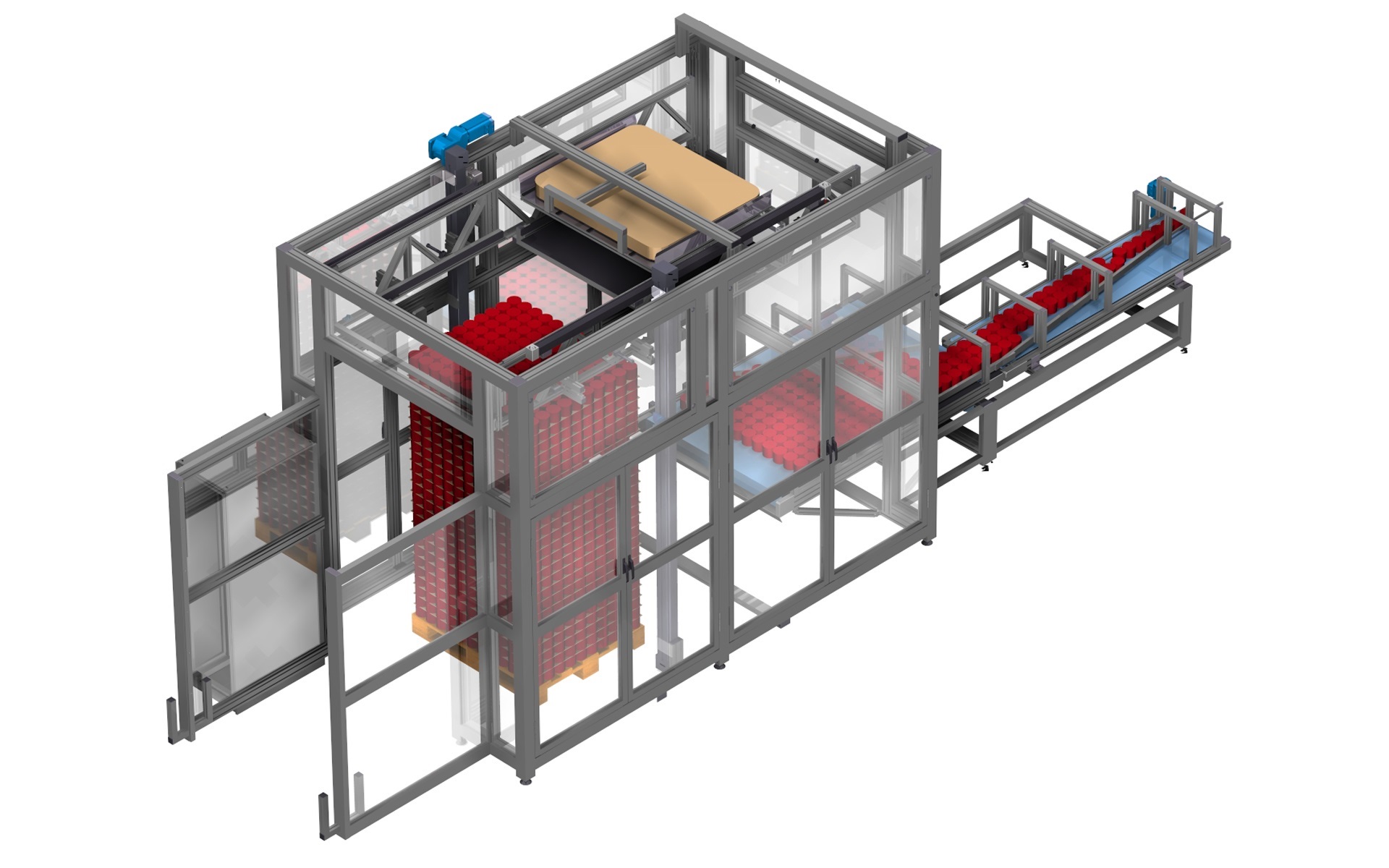

EXAMPLE IMAGES - FOR ILLUSTRATION PURPOSES ONLY

-

Used High Level Case Depalletizer

-

Used High Level Case Depalletizer

-

Used High Level Case Depalletizer