Integrated Rotary Rinsers in Triblocks

BPDM can supply a variety of used rinser/filler/capper triblocks, either as-is, reconditioned or rebuilt. Machines are also commonly supplied ready for production.

Go Back to Rotary Rinser Page

Learn More About Berks Plant Design and Maintenance, Inc.

Why Companies Do It

Rotary Bottle Rinsers are many times integrated with a rotary filler and rotary capper to produce a single triblock rinser/filler/capper. This is normally used to allow high speed operation and production to not be interrupted when products interchange from conveyor to conveyor, in this case the machine operates while the containers are controlled all of the time. Neck Handling of containers has become extremely popular, especially while accommodating lightweight containers, however is not a requirement.

EXAMPLE IMAGES - FOR ILLUSTRATION PURPOSES ONLY

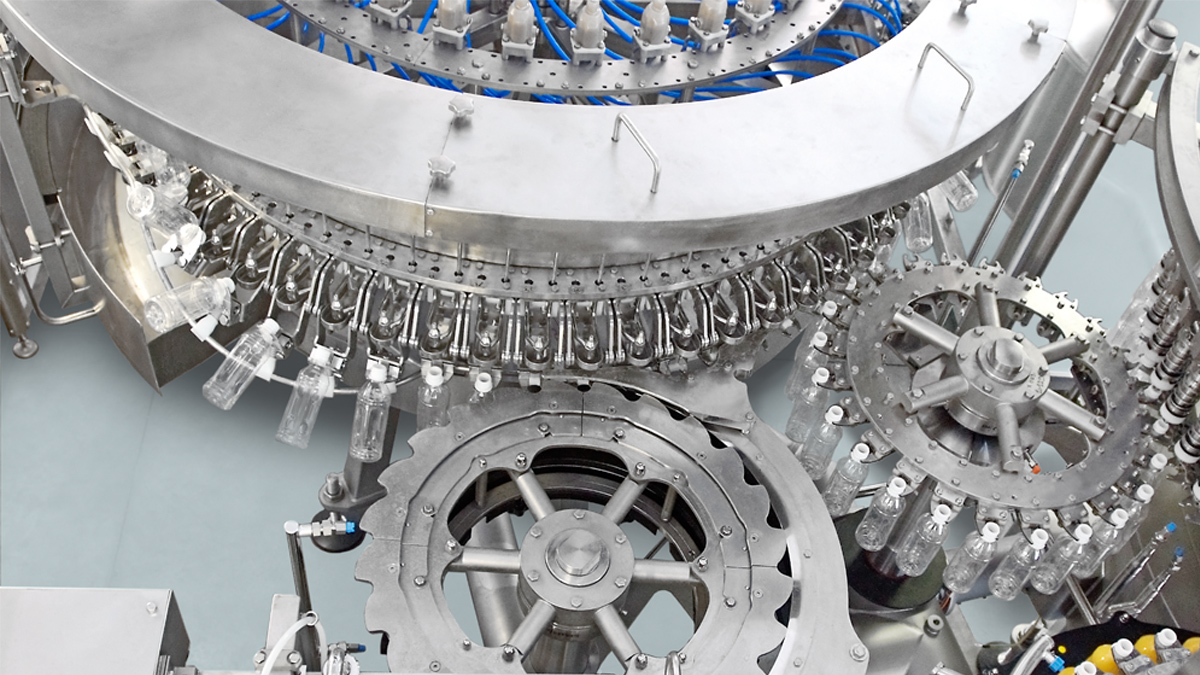

Infeed and discharge of rinser in a triblock rinser/filler/capper.

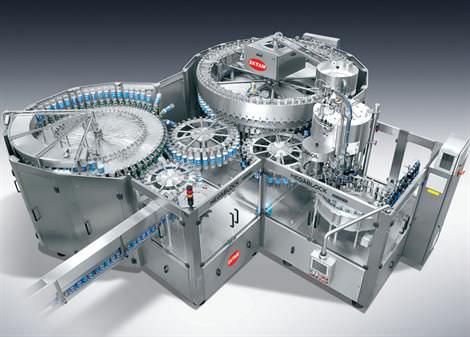

Overview of a triblock rinser/filler/capper.

Triblock: Rotary Rinsers integrated with both a filler and capping turret also known as a Triblock, is one completely integrated machine that can rinse, fill, and cap. These units complete the three operations, all while containers are maintained on pitch and controlled the entire way through the Triblock system.

Use of the Triblock system in a packaging line allows for increases in production while enjoying less down time due to the tight integration of the three different operations into one close knit machine. A significant amount of space is saved when these machines are put into the line compared to their non-integrated counter parts.