Used Semi-Automatic Case Tapers

BPDM stocks a wide variety of Used Semi-Automatic Case Tapers.

Other Types of Used Case Sealers and Case Tapers

Learn More About Berks Plant Design and Maintenance, Inc.

HOW IT WORKS

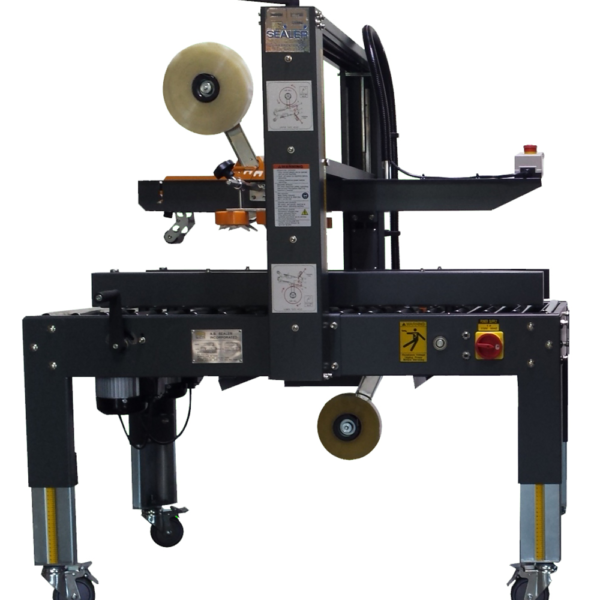

Used Semi-Automatic Case Tapers are used in production environments where a run of the same sized cases is made, then changed over for the next sized box. Used Semi-Automatic Case Tapers are used primarily in order picking operations where the size of the box changes with every order, requiring a case sealer that can automatically adjust to different sizes on demand. Used Semi-Automatic Case Tapers require the operator to close the flaps prior to insertion into case sealer. After sealing the center line of the box another type of machine called an edge sealer can be added to tape the four edges of the box to make what is known as an "H" seal.

COMMERCIAL APPLICATION

Used Semi-Automatic Case Tapers are manufactured in a variety of configurations suitable for your needs. Used Semi-Automatic Case Tapers are the most commonly used on production lines since each case is the same size as the previous case. Used Semi-Automatic Case Tapers change over very easily from one size to another in a matter of a couple minutes.

Used Random Semi-Automatic Case Tapers are ideal for order picking operations where the size of the case varies from case to case. Used Random Semi-Automatic Case Tapers automatically adjust to the size of each case as it is presented. Used Random Semi-Automatic Case Tapers runs much slower and cost a lot more than Uniform case sealers because of the extra mechanisms that adjust the machine individually for each case.

EXAMPLE IMAGES

-

Used Semi-Automatic Case Taper

-

Used Semi-Automatic Case Taper

-

Used Semi-Automatic Case Taper