Used Wrap and Neck Rotary Hot Melt Labelers

BPDM stocks a wide variety of Used Wrap and Neck Rotary Hot Melt Labelers.

Other Types of Rotary Hot Melt Labelers

Learn More About Berks Plant Design and Maintenance, Inc.

HOW IT WORKS

Used Wrap and Neck Rotary Hot Melt Labelers have the labels stacked into a labeler magazine. The can or bottle will rotate within the labeler. From here, the “pick up†area of the container has a strip of hot melt glue applied to it. The label will still to the glue and wrap itself around the container. A second strip of hot met glue is applied to the trailing edge of the label. The second strip will overlap the first strip, fully wrapping the label.

COMMERCIAL APPLICATION

Used Wrap and Neck Rotary Hot Melt Labelers are used for labeling of water bottles, soda bottles, tea bottles, food cans, vegetable cans, soup cans, fruit and nut cans, and seafood cans. Used Wrap and Neck Rotary Hot Melt Labelers are high-speed machines used mostly in wrap-around labeling applications. Majority of can products are labeled using rotary hot melt labelers. This is due to the lack of appeal visually that cans already have.

EXAMPLE IMAGES

-

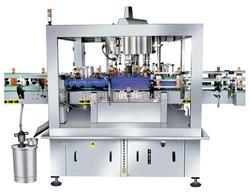

Used Wrap and Neck Rotary Hot Melt Labeler

-

Used Wrap and Neck Rotary Hot Melt Labeler

-

Used Wrap and Neck Rotary Hot Melt Labeler