Used Induction Sealers

Used Induction Sealers became very popular after product tampering cases took place some years ago. The induction sealing machines are designed to affix a liner or lid of some type using a magnetic field to heat up a metalized material thus melting the adhesive and bonding it to the surface it is in contact with.

Used Hand Held Heat Induction Sealers, Used Air Cooled Induction Sealers, and Used Liquid Cooled Induction Sealers

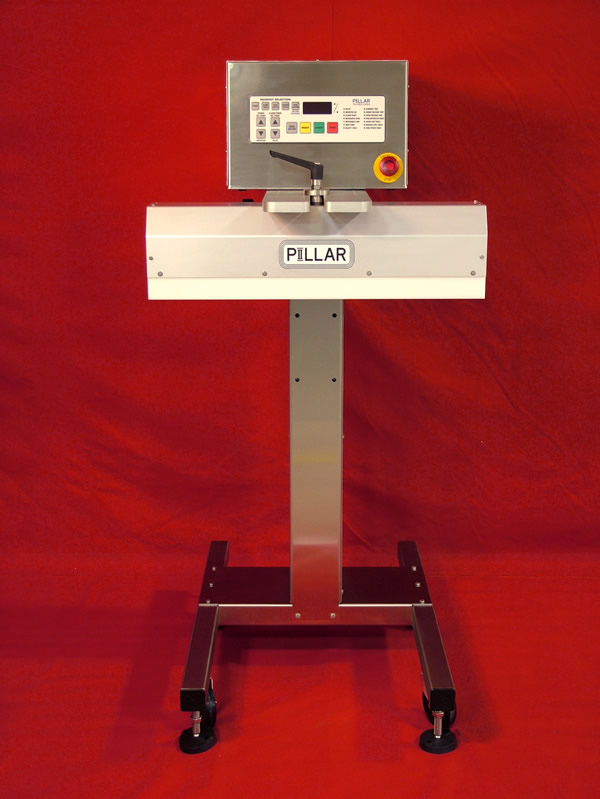

There are different induction sealer models for different applications but they primarily all do the same function. There are hand held heat induction sealer units for small quantity runs or lab needs. Another type is an air cooled induction sealer machine that is adequate up to 100 or so liners per minute (depending on cap size). The final type or higher speed machines are liquid cooled induction sealers. The liquid cooling is required because of the heat generated by the magnetic field strength needed for sealing at elevated line speeds.

Used Cap Torquer and Used Cap Tighteners

One thing to consider when using induction sealer equipment is the cap tightness after the seal function takes place. Some torque may be lost because of the seal shrinkage and additional cap tightening may be required. To handle this, a cap torquer (tightener) should be installed. This can be either an in-line or chuck style cap tightener.