Used Front Back and Neck Rotary Pressure Sensitive Labelers

BPDM stocks a wide variety of Used Front Back and Neck Rotary Pressure Sensitive Labelers.

Other Types of Rotary Pressure Sensitive Labelers

Learn More About Berks Plant Design and Maintenance, Inc.

HOW IT WORKS

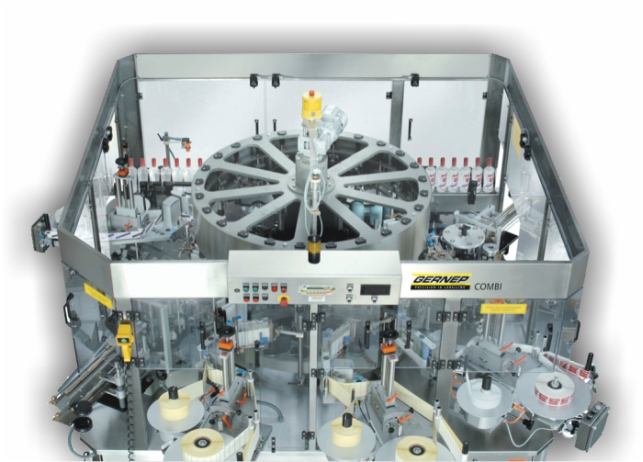

Used Front Back and Neck Rotary Pressure Sensitive Labelers use labels that were put on to an indexing reel. After the label strip is unwound from the roll. The roll, it is fed through self-tensioning idler arms to the peel plate and take-up reel. Indexed labels get put over a peel plat that is pointed in shape. When indexing the backing material over the point the label is released by the peel plate. The "flagged" label is now ready for self-adhesive to be applied and then placed on the container.

An infeed conveyor brings the containers in and they are transferred to the rotating turret. A bottle plate is there which supports the bottom of the container. Used Front Back and Neck Rotary Pressure Sensitive Labelers also have a spindle and with a centering bell which supports the top of the container. The containers travel through the rotary pressure sensitive labeler to a labeling station where the previously "flagged" label is waiting to be applied. Used Front Back and Neck Rotary Pressure Sensitive Labelers then use brushes or rollers to apply pressure to the applied “flagged†label. This process allows the label to stick to the container.

COMMERCIAL APPLICATION

Used Front Back and Neck Rotary Pressure Sensitive Labelers are mainly used for labeling products in cans or bottles such as wine bottles, beer bottles, health and beauty products, and aerosol cans. Used Front Back and Neck Rotary Pressure Sensitive Labelers are found in high-speed bottle and can labeling applications. A rotating turret or table is typically used and allows increased dwell time.

EXAMPLE IMAGES

-

Used Front Back and Neck Rotary Pressure Sensitive Labeler

-

Used Front Back and Neck Rotary Pressure Sensitive Labeler

-

Used Front Back and Neck Rotary Pressure Sensitive Labeler