Used Rotary Hot Melt Glue Labelers

BPDM stocks a wide variety of new & used Used Rotary Hot Melt Glue Labelers customized for specific applications and requirements in all industries.

Other Types of Hot Melt Glue Labelers

Learn More About Berks Plant Design and Maintenance, Inc.

HOW IT WORKS

Used Rotary Hot Melt Glue Labelers are used as an extremely cost efficient form of labeling by using a minimal amount of glue to apply labels onto a product. Labeling starts by having a line of glue placed vertically on the leading edge of the product. The revolving product takes a label from the label magazine and then continues to spin, as this is happening a second line of glue is placed vertically on the trailing edge of the product. As the product continues to spin Used Rotary Hot Melt Glue Labelers apply the label on to the trailing glue line and finishes the labeling process.

COMMERICAL APPLICATION

Used Rotary Hot Melt Glue Labelers can produce products at varying speeds depending on the length of the label being used. Speeds can start at. Used Rotary Hot Melt Glue Labelers are used to multiple different items from multiple industries including (but not limited to) plastic containers, metal containers, and glass containers. Wrap-around labels are the prime choice of label type with the Rotary Hot Melt Glue Labeler.

EXAMPLE IMAGES

-

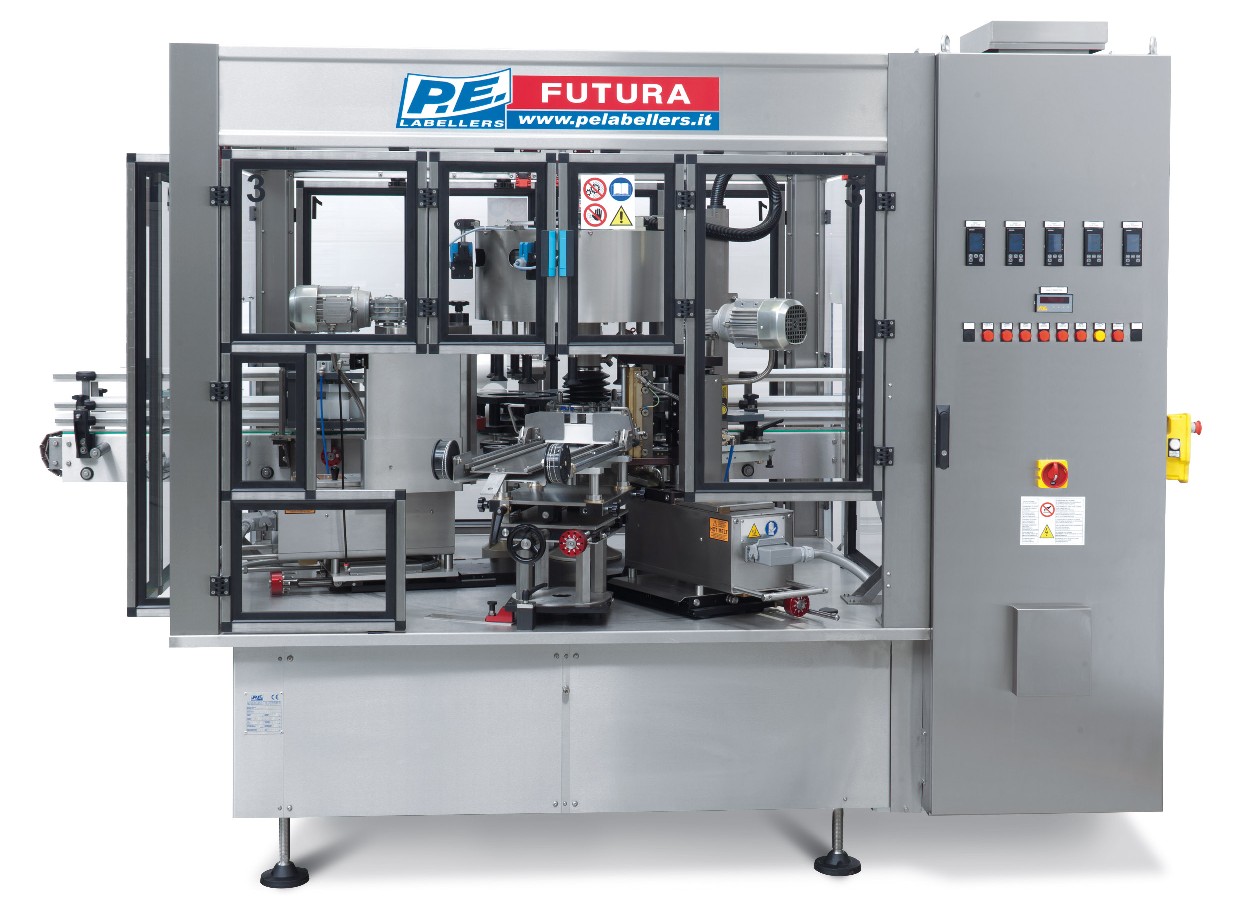

Used Rotary Hot Melt Glue Labeler

-

Used Rotary Hot Melt Glue Labeler

-

Used Rotary Hot Melt Glue Labeler